Webcast: MES Manufacturing Execution Systems

Today's webcast we are going to spend a few minutes talking about the 4th Industrial Revolution that we are now part of, and where technology has gone. We are going to focus more deeply on Production Coach.

Industrial Revolutions: a few items to point out, we all understand that we are in an interesting day and time, technology is moving quickly, the internet has changed the way we work, act and think. Roughly towards the end of the 18th century, we termed it to be the 1st industrial revolution, in 1784 was the first mechanical weaving loom, which was a huge advancement of industry to be moving from a manual process to a mechanical processes. It wasn't for about another 100 years that we saw the second industrial revolution, that started in Cincinnati around 1870 in a packing house, with production lines.

In a much shorter amount of time in around 70 years we started to see the first programmable logic controller or PLC, that allowed us to begin to have computers talking to computers. In even a shorter amount of time we have our 4th industrial revolution, and we are going to focus on it today.

If you see the trend in timing a 100 years between the first and second, 70 years between the second and third and only 40 years between the third and fourth. Certainly, technology is moving faster and time between each is shrinking and it is shrinking at the pace at the technical advancement.

That puts us in a unique position, that we need to fully understand what Industry 4.0 is and how that can have an effect on us.

When we think about Industry 4.0 we have to understand that it is impacted by the Internet of Things and the Internet of Services. It is the communication between bots, employees, machines and all of the devices we are using

There are six design principles that have to do with Industry 4.0:

- Interoperability - its all things working together, communication between all things.

- Virtualization - We might think about that as virtual imagining, virtual servers, clouds or even operating systems.

- Decentralization - Is were local decision are made real time instead of being centralized.

- Real Time Capabilities - or automated feed back to gain information from the office, the shop floor and all aspects of manufacturing.

- Service Orientation - Is were everything is focused around the customer experience.

- Modularity - Were not one-size-fits all, where it is possible to integrate new Industry 4.0 thinking into even existing factories and operations.

The internet of things has been a great change, example if you give a young person an electronic device, a computer they have the ability to pickup and utilize in ways that are not common for us that a little bit older.

Yesterday is behind us and were we thought the great revolution was a computer talking to a computer. Tomorrow is were we need to head, but what is Industry 4.0 and how can we make that applicable for today?

Most of us can't build all new factories and equip them with the latest equipment and controllers but we can use the influence and understanding and principles of Industry 4.0 in our future decisions.

Here are few examples of Industry 4.0 technologies:

- POS - Point of Sale it is web commerce, highly configurable, fully parametric and were sales order can come instance production orders with out manual entry.

- CAD|CAM is real engineer to order cad-cam, that can manage all aspects of production and engineering and not just simple boxes.

- Optimization/Nesting - One database driving one or both nesting and optimization as well as managing the creation and use of usable scrap.

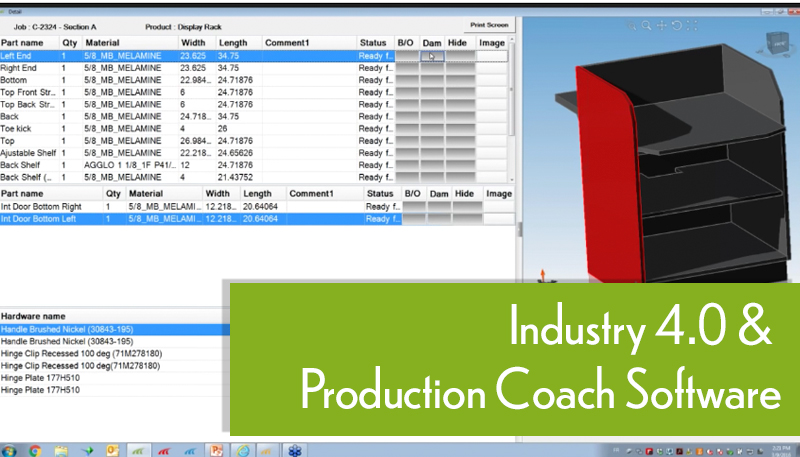

I want most of our focus today to be around what is Production Coach Software, it is a control system for managing and monitoring work-in-process on a factory floor. An Production Caoch keeps track of all manufacturing information in real time, receiving up-to-the minute data from robots, machine monitors and employees.

How much does it cost, not the software but how much does it cost when assembly starts but can't finish because a part is missing or damage? What does it cost each time that production has to come to the office for information? What does it cost for manually finding out where something is in production? What does it cost for all of the shop paperwork? And what does it cost to expedite part shipment because there wasn't damage part alerts allowing for quick decisions?

I know in talking with customers that all of these are very costly to businesses sometime its difficult to know how to put a dollar value on these, these but they are certainly expensive.

Industry 4.0 and Production Coach is giving you the ability to get a real-time, 360 degree view of your factory's operations, control and view your entire production, eliminating physical files and follow your projects' progress in real-time. With Production Coach many things can be achieved.

One of the design principles of Industry 4.0 is of course Modularity, you don't have to be interested in doing all aspects of Production Coach to gain benefit from it. You will be able to import from CAD|CAM so that would mean so instead of having to replace your current design, engineering and outputting manufacturing or g-code data you can utilize existing engineering software i.e. woodCAD|CAM, cabinetVision or Microvellum. - That is all things working together, the very first design principle or Industry 4.0.

Being able to help with the planning and organization of what will occur on the shop floor, how are we going to release to manufacturing. Being able to enhance data to create automated sorting and routing information back to the part labels. Being able to track the progress of work orders on the shop floor, or with automated machine feedback. To use the design principle for Decentralization to allow people on the shop floor to create automated Part Alerts, so quick decisions can be made from management. Visualization and the ability, the design principle was related to cyber being able to visualize what can happen on the fly. Kitting the ability to organize items for shipment that might not be part of the assembly, i.e. lose hardware, molding. Then be able to track the items make it on to the truck to verify nothing is missing.

Data Enrichment - is the ability to not only receive data from your existing CAD/CAM but be able to push information organized back to it so that part labels coming from it can have things for sorting.

Automated Feedback - with technologies like HOMAG PowerTouch control with automated feedback it is possible for Production Coach Software to be receiving feedback as to the progress production with out human intervention.

Next Jonathan Saucier with Web-Cab smart solutions is going to take a few minutes to talk about his company, their vision and to show you demo of their software.

Who is Web-Cab - we are a team specialized in developing and implementing smart solutions for the woodworking industry. We have more than 2700 optimized users. Our main goals are innovation, customers service, loyalty, cooperation and unity. Our mission is to bring your productivity to the next level by optimizing your day to day processes with proven simple and reliable solutions.

Next will be a demonstration of Web-Cab and then question and answer session.