Production Coach: Real Customers. Real Transformation. Real Profits

Welcome to the webcast so happy that you decided to join us today. I really look forward to this particular session, this is not a software presentation but a great experience for those of you who are considering Production Coach. You'll get to hear today from some great customers and get to learn a little bit more about their experiences. I think that will make it just a really super good experience for you.

The purpose of this webcast is for those that are considering Production Coach can get a perspective from people who have already made the investment and are in the process of utilizing or expanding what they're doing with it.

So what I'll begin with today is just a little quick review directly from our website, you might notice that I'm here at www.rsasolutions.com, under the products tab then Production Coach .

What kinds of things might customers expect well first of all please understand that the system is highly modular meaning that you can do as much or as little with it as you would like. From the very most basic of making a product label and shipping out the door, to being able to have vast numbers of stations or even a reasonable number of the modules that are available with them.

I will cover some of those to help you have a better understanding of the tremendous increase in throughput.

That's one of the things that I hear over and over from customers is that they were really, really surprised about, all of the small accumulated things of improving communications and flow and managed the things that has enabled them to increase their throughput tremendously.

Problem number two, widely happening in our industry is not shipping 100% accurate a 100% of the time.Production Coach makes it so clearly obviously you can't get the wrong things on the truck and makes sure you get all of the right things on it as well. Being able to manage outside of the factory itself all the way to the jobsite for deliveries and installation, that's been huge help to our customers.

Then I would say that certainly ranking high is sorting, the automation of assembly for customers that has really helped them organized the chaos to be able to ensure that they're only building what's ready to build with all the right tools that they need.

Next of course being able to manage damaged or missing parts in the process, to give you good insight into your business whether that's constraints or bottlenecks. Those kinds of things, having historical big data over time, to be able to have great data analysis. Then of course helping with other things such as time keeping.

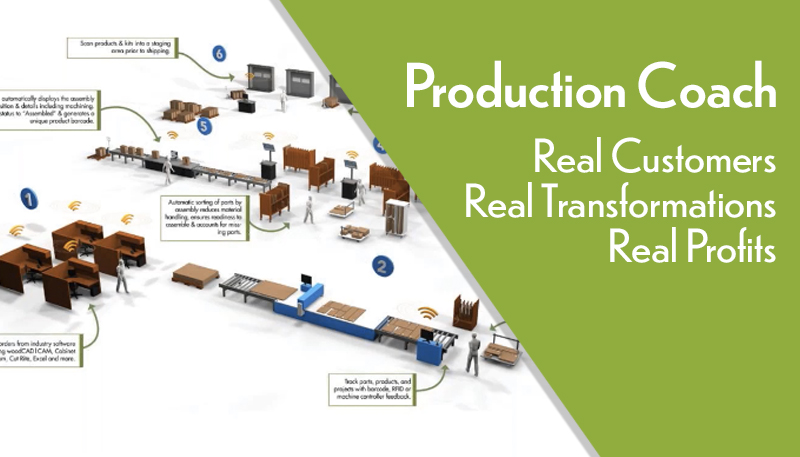

I'm going to move to the image of the 3D factory and just go through these eight displayed numbers on the screen, so that you get a little bit of visualization as to what is happening and hopefully that will make sense.

First of all one of the great attributes of Production Coach is the ability to harness data so if you're using some kind of a CAD/CAM system, popular to our industry right now would be woodCAD|CAM, you know Cabinet Vision, Microvellum, Cut Rite or even other solutions.

Production Coach has the ability to be able to import the data directly from those, so we know the products in the work order, all the parts the hardware all of the information about that, just literally in a very slick and quick ability to import. From the same kind of office position you may want to consider doing a number of things other than just the management or setup of the system which could include creating shipping tickets, attaching documentation to the work order, being able to move your process into more of a paperless kind of a world.

This again is meant as a general overview, so I won't talk about all of the possible things that you can do, but just know that from the office it's very, very easy to be able to provide for production in an electronic work order containing all the information they need to do their jobs effectively.

Item number two is depicting a first operation in the shop, it's really common for customers to want to track at first operation whether that is panel saws, nested based machines whatever that first operation is. It's common to want to know when a work order has started in production and to be able to have that kind of tracking. Of course, you can have whatever number of stations that you might want to know various tracking at.

Item number three is really depicting that while you can you don't have to, I picked a couple of operations that commonly our customers skip such as edge banding or horizontal bore and dowel insertion. You might say well why would they not want to track that, you can imagine that flowing through production, if we knew that it was cut at the saw, we know that it was made at the C&C and we're getting ready to take it into the pre-assembly area. As long as we have it accounted for there, we can assume the others were done or you can have those as tracking stations as well.

Number four is probably one of the bigger features of Production Coach although not all of our customers choose to use it, but sorting is very amazing. If we said we had a work order that is averaging 30 to 40 let's take 35 as the median, 10 parts each that's 350 parts and a work order flowing through towards assembly. Station four allows us just to scan a barcode on a part and organize all the parts very, very quickly by product. So that we have a real understanding of what's available to be assembled and what might be missing, a great station also for QC as well.

Then station five depicts our 3D assembly so communication with the sorting, by the way I might mention also the sorting is not limited to one type of sorting for some of our customers they sort case parts separate from doors and drawer fronts some even separate from drawer boxes and some even separate from toe base assemblies. We have the ability at station five to synchronize all of that together and to give assembly not only a 3D image of what they're building but all the parts, all the fronts, all the hardware we're going to generate for them. Then a product label that will update the product status in the system to let us know that it's been built as well.

Also of course having the ability under number five to be able to generate kits or pallets either of loose item products on pallets, whatever things you might want to do stage the job preparedness for shipping by make sure that everything is done and complete.

Then of course number six showing us not only that along with seven to scan directly on to the truck so that we make sure that we shipped 100% accurate 100% of the time.

Then finally at station eight is displaying what we would think of as the jobsite tracking so having the same kind of ability to help manage the factory or the manufacturing execution to be able to help ensure that the right things get offloaded from the truck. We can have status updates as to what's been delivered, what's been installed, being able to automatically generate damaged part alerts directly back to the factory or whatever it is needed to be able to do a great job.

Just real quick a few screens and we'll move on to the customer interviews.

Production Coach of course that allows you to import your work orders, those display on the left-hand side and a really nice GUI interface needs to be simple enough that people don't need vast training just by looking at the screen, it all makes sense. Upper section is what we refer to as assemblies you know that the cabinet's, the countertops, the fixtures whatever it might be and the lower section is the item that are loose or not part of the assemblies, that we in some way need to manage whether that is creating kits or whatever needs to happen with those items.

Again, many of the modules within Production Coach you know are optional for some of our customers they use our Google Calendar integration to be able to do finite work orders, scheduling and to track at a really, really great level to know the completion or status of all work orders at any kind of a station, because we utilize Google Calendar means because that information is also available from any internet-enabled or smart device. So, you could be on the golf course and someone calls wanting to know where the job status is and you would know that instantaneously.

Business intelligence board is key metrics that we might care about in our business, being able to see are we running in a balanced workflow, do we have any constraints, or bottlenecks that we need to be alerted by. Are we keeping up with our performance by station according to our productivity goals what kind of quality are we producing? Here's a great example not only can you run in the live mode, but you can also look at this data deferred over time so maybe I

want to know over the last six months what was the leading cause for damaged parts in my factory.

If I know that kind of information I can you know proactively decide to do some operator training machine maintenance and whatever might be required to eliminate those kinds of problems. Of course, you can see the work order status directly from the interface itself at a finite level and again via the Google Calendar at the completion of any station. Damage part alerts and management of those things have been a tremendous help to many of our customers and are available to be reported from any Production Coach station and/or the job site tracking module, and can be an alert that automatically pops up at whatever station that you might want it to

For some of our customers they utilize Production Coach in the tracking of time either for the purposes of payroll and order for work order costing, it literally allows you to have a very granular detailed level if you like, down not only to how many hours attributed to a work order but also by department and/or by task under department. I'm sure some of our at least one of our panelists today will probably cover that.

Just another module, smart labels on demand we took what people were doing with labels on demand at CNC routers and made it astronomically better not only is that giving us part barcodes for each of the parts of showing orientation of the bar code so that edges get banded properly it is sequencing the offloading of it it's pacing the operator and again updating the system among other features.

I mentioned back in the 3D Factory at station number four with sorting there's a photographic image of one of our customers sorting racks they can either be fixed racks sorting multiple work orders or mobile carts, really to any configuration you want. So, it's going to show you exactly where everything gets staged, if when you scan a barcode it turns red you displace it there it turns green when all the parts are there.

This is the 3D assembly view so just literally by scanning any part label it's going to automatically pull up a 3D visualization, you have complete control over being able to see below it behind it inside it able to turn on or off part see the front as well as the hardware. Also generating we talked about the loose items when we first began and so this is a matter of being able to have one singular barcode that's representing a pallet or a pack or kit commonly for customers that might be molding bundles, hardware bags or in this case it's displaying a pack of adjustable shelves as well.

Being able to stage and organize work orders to make sure everything is ready and prepared for when shipping is time being, able to scan everything on the truck and ensure 100% accurate shipments 100% of the time. Finally again, the jobsite tracking what we're able to literally scan coming off of the truck or as products are being installed as well.

I'm ready begin conducting the customer interviews and I'm really excited about that and want to go ahead and get started so Kent if you would please unmute yourself but allow me to make a little bit of an introduction to the team. So, Kent Swenson a great friend of mine owner of Timberline Cabinetry and Millwork out of Manhattan, Kansas is joining us today. Kent has a pretty vast experience with Production Coach actually he was one of our very first implementations in the United States and Kent is a really savvy guy not only with production but software. Kent if you would please again tell everybody just a little bit about Timberline Cabinetry and Millwork

[Kent Swenson] So we do primarily commercial millwork, we have anywhere from 15 to 25 employees in the shop depending on the time of the year and the season what we're working on. Production Coach has given us the ability to manage things much smoother and more fluidly and stop the herky-jerky action that we struggle with so much in our industry, so it's really, really important for us.

[Shawn Maberry] That's awesome thank you appreciate learning a little bit about Timberline fabulous business you could eat off the floors for sure it's really good. So, tell us a little bit the things that I'm going to kind of cover with each of the panelists, are things that I believe are important for customers or prospects of Production Coach to better understand.

[Shawn] So Kent one of the fears that people have about implementing software is that it's going to take a long time it's going to be more difficult than the salesperson said that it was and you know that it's just going to be a bunch of unexpected costs and stuff. So, would you tell everybody about your experience with integrating Production Coach when you got started?

[Kent] So although all the problems and concerns that you just voiced have been my experience with every other piece of software that we've ever installed, with the exception of Production Coach. So when we purchased Production Coach we took it upon ourselves to get the computers installed on the shop floor, we loaded the software, we hooked up the monitors and the barcode scanners, we did that stuff so that when the integrator came on site to help us get it set up that was already ready to go. So, all he had to do was show us how to use the software and how to load our work orders into the system. He was here for one day and in one day we were trained how to use it and we were functional, the next day we were actually using it in production. Now as time progresses you find more and more opportunities and things that you can use it for to solve problems that you have and that requires then that you go possibly change the source data so that you now have some information that allows Production Coach to do whatever it is that you want it to do. But the actual setup of the system and getting it ready to run is literally like falling off of a log.

[Shawn] That's awesome thank you very much thank you and so second question would be let's talk about the before and after a little bit. I was I was blessed enough to be at one of the Factory Tours we did at your facility and I remember you sharing with the people who were in attendance some of the big changes that happen, I think you talked about square footage, about personnel, about equipment and what that did related to throughput results. So can you give us a little idea of what really is the impact of Production Coach in your factory?

[Kent] So for us the tremendous benefits that we get out of it are at the assembly and the shipping department. Prior to implementing Production Coach it took us hours and hours to sort parts out for a work order so that we get all the parts for each cabinet in a pile ready to build and it took a fair amount of skill and experience for the person doing that to recognize what the parts were and which parts they needed and which parts were missing and it was a very difficult, painful process. Now we can take someone a new employee that comes in off the street and literally in 15 minutes they can be productive and sorting all the parts out for a work order with 15 minutes of training and getting it right. The amount of work that we can now get through assembly has tripled using the same square footage the same equipment and the same bodies. So, prior to Production Coach we could do 30 boxes a day, was pushing it we can now do it's a lot of effort but we can do 80 to 90 boxes a day with that with that same setup because of the benefits that it's gained us.

The other thing is the now in shipping we're able to because Production Coach keeps track of everything as it's moving through the process. We know that everything in a work order is complete before it ships, we know this if something is missing, we also know when it comes time to ship what's supposed to go on the truck and as we start loading it Production Coach keeps track of what actually got loaded versus what was supposed to be loaded. It lets us know before we leave that hey, we're missing two things and gives us a packing list that's generated specifically and automatically by what is scanned onto the truck.

So that there is no haggling over the GC on the other end about, “well did you really deliver this or not” well the only on it shows up on the packing list is if we scanned it, so yes its complete. So now they're much more trusting of us on the other end because they see that everything that's on the packing list, if we say it's there it's there.

[Shawn] That’s awesome I just want to make sure I heard you correct your statement so if this is rephrasing but I think that heard you say, prior to Production Coach you are through putting around 30 boxes after Production Codes with no additional employees, no additional equipment, and no additional square footage or area for it that it tripled the throughput?

[Kent] That is correct it's a it's a hard push and its hard work and we're hustling and we're moving but we can get that done so yes it tripled our capacity.

[Shawn] Last thing, if you were going to give advice to anyone attending the webcast today that's considering Production Coach what would be the best advice for them you can think of?

[Kent] I'd say go see it in action at somebody else that does what you do and see what it saved them and see with your own eyes, if someone had told me that I was going to see a 300% increase in my capacity, through an area particularly one that's problematic like assembly. I wouldn't have believed him in any way shape or form but seeing it with your own eyes and on all of the little intricacies and all of the individual little problems that it solves. It's the accumulation of all the savings of each one of those little individual solutions that get you to that point where you're able to do three times more than you could before. It’s not just one simple little thing that you can just stick your finger on say oh well that's obvious it's a bunch of small little things that all accumulate together to be enormous savings. So, seeing it with your own eyes is truly the as some people like to say the proof is in the pudding.

[Shawn] It's awesome Kent can't thank you so much again at the latter portion of the webcast will open up question and answer with the people on and so if you do have the time hang around and might be a question or two for you before we're done thank you Kent.

[Shawn] Caleb would you unmute yourself please quick introduction this is Caleb Carpenter from Homestead Cabinetry out of Hiram, Utah and Caleb has been the brains in making all this work together for Homestead that he and I have been working together for quite a while so anyway Thank You Caleb.

[Shawn] Tell everybody a little bit about a little bit about Homestead if you would?

[Caleb] So Homestead is a high-end custom cabinet shop we do almost exclusively residential work. We do lots of lots of acrylic and laminate, but we also do lots of finished work. We are a shop of probably around 50 people, and we do somewhere between a normal day across we produce somewhere between 100 and 120 boxes.

[Shawn] Awesome great then beautiful factory as well but I have to say customers that I get to frequent, every single time I'm there it looks completely different than the time before so these guys like shuffling and moving and firing processes and making it all better and better and better so it's a great business. The same kind of question that I asked Kent, obviously it's a concern for prospects how integration is going to go and so give these guys a little idea about what to expect to experience.

[Caleb] I would echo some of what Ken said that compared to most software setups Production Coach goes pretty smoothly. Our particular experience was not quite as smooth as Kent’s but that's at least partially because of a mistake on our part which I will explain but overall the integration went pretty well. The mistake was that Shawn has mentioned that Production Coach is very modular, it's very easy to add new stations to add new computer terminals it's very easy to reconfigure those terminals so that they function differently.

Our mistake was we tried to figure out everything we could possibly need Production Coach for ahead of time and we bought it all at once we bought something like 14 stations which was too many. So, our integration process turned out to be more complex than it needed to be because we started too big. So, my advice to people interested in Production Coach is don't worry about don't worry about figuring out every little detail about how you will use it and where and why.

Start with just a couple of stations use them in a couple of key places in your shop get to know the software, once you do it will be easy to add bits and pieces and expand it out into the rest of your shop, you don't need to have all of all the questions answered right up front.

[Shawn] That is really good I probably should have asked you for the customer or the prospect advice first knowing that that was certainly a situation when these guys got discovered they were in a situation to where they had a mindset and that is we don't want any surprises we want to make sure that we get everything that we need you know all at one time. And obviously I think his advice here is the “KISS” keep it super simple and just know that it really is super easy to add on so that's awesome. Caleb would you tell us a little bit about the results you know kind of their before and after what's it done to impact Homestead?

[Caleb] So the impact of Production Coach at Homestead has been huge I mentioned that we do some around 120 boxes a day, before Production Coach our average was between 30 and 40 so we've tripled that and if we really push I think our record was, I think we did 250 bucks as a day for a week once so our capacity is much, much larger than it used to be.

Last year was our most profitable year ever and we did that with ten people fewer than average, so we use to have an average of 60 people every year, last year was our most profitable and with 50 people instead of 60. The part are our shop were it helped the most, first one I'd mentioned would be the sorting station prior to Production Coach we had a similar problem to what Kent mentioned we're keeping everything organized by cabinet when it arrived in assembly was quite a headache.

We operate with nested CNC routers and we had our nest set up so that cabinet parts for every cabinet came off grouped more or less together and from cut out, on every single department would put effort into keeping the cabinets organized keeping all the parts grouped by cabinet.

Which meant inefficient nests it meant a lot of extra effort for the cut-out guys and for edge banding to keep everything organized and all of their effort notwithstanding things would still go missing before they reached assembly. Our assembly guys probably spent 40 percent of their time just hunting down stuff that wasn't there.

I'm sure all of you will be familiar with the headache of getting a cabinet partway built and then discovering you don't have what you need to finish it, whether it's a cabinet park or hardware old doors and Production Coach is what solves those headaches for us. With the installation of a sorting station just upstream from assembly, first of all that allowed us to decouple cut out and edge banding from the sorting process, our cut out department now nests everything however is most efficient and group things by all they worry about grouping them by us by cart type so that it's easier for edge banding edge banding doesn't worry about organizing parts at all he just runs things and then throws them on a cart at random.

When the parts arrived at the sorting station it takes 15 to 20 minutes to sort out all of the parts for a job and it's accurate its complete everything’s there, so no cabinet ever gets into assembly until everything is accounted for. Once a cabinet starts an assembly it flows all the way through it doesn't stop it doesn't get hung up by anything. Assembly is far more efficient much less of a headache than it used to be. It's probably still the bottleneck in the shop but it's a bottleneck that can do three to five times what it used to. The other place where it made a big difference was in shipping other major headache was dealers calling us and saying hey you never shipped this part and before Production Coach we had no way of knowing whether that was true or not. We spent a lot of time and money will be making in shipping parts that we don't manufacture. Now when we send a job to a site and they call us and say something that's something is missing we just glanced through Production Coach and we can say exactly what did and did not get shipped. We can confirm to them that it was loaded onto the truck at a certain day and time so yes, they do have. That's also helpful there has been the palletizing feature because a fairly common thing that we do is to bundle moldings together and so moldings from a couple of different rooms that get bundled together and the dealer would call us claiming that we never sent the molding for a specific group. But now we're able when that sort of thing happens tell them we did ship it and it's bundled in this bundle with this number with the moldings from these other rooms. They're able to hunt it down and find it so we spend much less time remaking things that that we’ve already made.

[Shawn] Yeah that's good I remember one time I received a text, they said magically our phone stopped ringing for all of these calls from. That's awesome you already gave about starting simple, keeping it simple and then expanding. Tell everybody what your experience has been related to service and support after the sale?

[Caleb] Service and support our experience has been great as part of the set up process they'll give you, if you choose to go with this option they will give you a an online account where you can go in and submit a ticket whenever you encounter a problem. In my experience I usually hear from Web-Cab, the company that does the software development, within a half an hour to try and get the problem solved. Very little waiting they're very on top of it they understand that then when something goes wrong it holds that production for us and they put a lot of priority into getting things fixed for us getting them up and running.

The other thing that RSA Solutions and Web-Cab does well with is a development, there have been a number of times when we've been using Production Coach and ended up thinking to ourselves you know it would be great if Production Coach had this particular feature that it doesn't currently have. When I call RSA Solutions and describe the feature that we'd like to them they’re very good at working with us and whenever possible getting that feature integrated.

We've had ideas for new features that they decided were would be beneficial to all of the customers in which they implemented for free but there have also been ideas that were beneficial to us in particular and they were able to work out a deal where we pay for the development of that particular feature and in both cases it's worked out very well for us.

[Shawn] That's awesome thank you very much for that if you do have time Caleb would appreciate if you hang around for the Q&A at the end of this case anybody's got any questions. I really, really appreciate that you helping people I know that it's the hardest part is making the decision and I think you said it really, really good don't get over stressed by thinking you have it all figured out it's so reconfigurable that that even if you had in your mind one way you could completely flip to something else.

Might also mention I'm really excited soon we'll be embarking on my first project with RFID at the level of sub-assemblies or door storefronts and I think that that's going to be another great step forward for Homestead since they do a lot of finishing of those components, not a real good way to be able to have barcode for that. Thank You Caleb appreciate it very, very much.

[Shawn] Jamie and again is what Phill’s Custom Cabinets out of Kentucky great guy, they have a great business and so I'm so happy that that you joined in an effort to kind of maybe help some of the people attending the webcast so they have a little better understanding of what it's like to choose the Production Coach so if you would tell us a little bit about Phill’s Custom Cabinets?

[Jamie] All right so those Phill’s Custom Cabinets is a 45 year old second generation custom cabinet operation like Shawn said in Western Kentucky unique thing about us is not only to be providing build full-out custom kitchens in residential settings we also do an outsourcing model as well. We have currently about 70 employees in a 75K square foot facility running multiple different operations united all the Production Coach .

[Shawn] That's awesome, wonderful so I kind of went through a little series if you've heard on here, tell us about what has your integration experience was like and if you don't mind this time let's kind of break it into two because you followed Caleb’s advice that he just gave on here and you started off pretty simple and recently you have significantly expanded so help everybody understand what integration 1 and 2 was like?

[Jamie] Okay so we actually began a few years ago we went and did a live event at Kent's place actually in Kansas and we were sold right off knew that it was a solution for us, many of the things that I talked about today we suffered as a manufacturer. Not being able to track parts scattered parts on organization going to the job lacking parts so we had a lot of desires that we want to look at and to fill.

We walked away from there knowing I think I've contacted Shawn on the way back saying no we're in we're gonna buy more company for me and at that point Shawn advised to the start small let's get it going and then and we'll see we're going, because my initial gut was I want to fix everything at one time. We did do Shawn advised us, and we bought a few stations I think six to start with. To do assembly and sorting primarily and then we did some creating and kidding with it as well and that was, I think we came online almost about two years ago now. What Shawn said we've added I believe we have I try counting this morning I can't remember up comment 18 to 20 different stations or different access points I guess it's for lack of a better term to call it for operations throughout the facility.

We've ramped up and we're going to continue to ramp up we're looking at for the needs that you have but it's definitely a great program from a stand point you can start small and medium and then you will grow and organically it develops and you'll see other places that you can plug it in and use it.

[Shawn] That is really awesome thank you very much for that so you remember how long or what the initial was like I mean as far as a duration did it was it harder or what would you what would you give somebody to say relative to integration experience?

[Jamie] It's a fast experience once you pull the trigger to do it, mine was really similar to Kent’s it was we had a gentleman come I think he as here for two and half days, and he installed the license and we set up all our own computers and stuff as well but he did install the licensing in the program did a training session for us on it and then was gone let us let us take it and run with it. From an integration standpoint in a learning curve it's really, really easy or compared to most other software's.

[Shawn] Yeah that's perfect Thank You Jamie and tell them a little bit about what's changed in your business as a result of it, obviously you you've dramatically grown the use of it and so it's done some things for you what would be you know kind of a tops one, two, three benefits of Production Coach ?

[Jamie] Well I think the biggest thing we're always trying to do is change the culture of our people and we were able to use from Production Coach in that sense to give them a surety of product when you want to give to their particular process they can say hey I know it's here because down streams check out the box and says that's here. Also given our sales force a surety of it as well as more confidence in speaking to our customers one when the product arrives at the facility. It’s really done more so from the culture standpoint for us than anything we are just beginning to harness now some of the dashboard aspects of it and trying to be some of the gamification with it to really motivate our employees more. From a tracking and a culture standpoint it's been the biggest benefit we’ve seen with it.

[Shawn] It's awesome wonderful and tell everybody you know I think one of the things people worry about is you know you get sold on something and then they're gone what has service and support then like since you made the decision to implement Production Coach ?

[Jamie] It's been great, I few glitches that we've had I was been able to send off an email and within twenty, thirty minutes they're back in touch with us and looking at and resolving it, and then we're off going again.

In two years we’ve maybe only used it two or three times, it’s just not something we've had that experience with, we will use it, but we really never had a need to use it.

[Shawn] Yeah even better right, okay well I got one more question for, so Jamie one of the things that obviously is really nice is to get advice from someone who's been there and done it and so what would be your main advice for people who are attending this webcast and considering Production Coach?

[Jamie] I would agree with what was said before, I go and kind of witness it in use, what sold it on us was going to Kent’s place. I actually seeing a demo on it and the lights are going off in our minds going yes you struggle with this or this right here would solve something, that way you experience the information. The website covers it really well however to just visually see it or even go to one of the trade shows or work they can run you through a complete demonstration on it but to see living and breathing really helps out a lot to be able to picture it in your own facility.

[Shawn] Yeah that's awesome thank you very much I appreciate that that is wonderful that's one of the reasons why we invest in of course the major trade shows while we do various manufacturing events that some of the machinery collaborators and why we host Factory Tours at various locations around the country so that people can have their own really great experience on it.

I might point out to everyone that's listening in we did something a little bit different for those that might not easily be able to travel. On our website at RSA Solution when you get to the page for Production Coach you'll notice is that there's a range of videos also available and in one of these you're going to see it's a near the center of that called Lutz Factory Tour an AWI shop just outside of Dallas and we had the entire experience videoed.

[Shawn – Viewer Question] I’ve had to jump in and out of this webcast I have, I need to track parts in various stages from CNC the delivery what is the best scheduling software that works with your system?

[Shawn Answer] So here's what I can say we have implemented a link to Google Calendar and we give you the ability since we're already importing all the data we know a number of metrics about the job we'll give you a variety of ways to use back scheduling logic and so it will plan the work orders and also display for you at any station any dates or any date ranges the load on that station from your productivity goal.

So, yes Production Coach can be tracking if you want it can be sorting if you want it can be shipping if you want and it also can help you with the ability to plan or schedule your work orders as well.

[Shawn ] I'm not going to cover the questions related to cost but specific things but please understand that the system being very modular, the price can range from endlessly from a very minor investment to get started and do some basic things to being able to blow up in a factory and utilize a lot of modules like some of these guys are doing as well. It does range what I can tell you is that while we have done some tracking about sale unusually we're looking at a range between 20 and 40 thousand however it can go below that and it can go above that but just to give you kind of a basic idea of what is going on.

[Shawn – View Question] Let's see what else but what design software our shops using?

[Shawn Answer] We have customers that are doing a wide variety of different softwares, I believe it would be fair to say that at Timberline currently he's running Microvellum and Cut Rite and that at Homestead they're doing the same thing with Microvellum and Cut Rite. At Phil’s I believe that you guys are using correct me if I'm wrong, but I think you have a combination between Cabinet Vision and KCD, Jamie can you respond to?

[Jamie] Yeah we actually use KCD, Cabinet Vision and then we're using the CAD Code software as well but we’re importing into Production Coach through the CSV which is another option that was available.

[Shawn] Yeah no doubt so I mean obviously we need to have that kind of a discussion but we have built imports to the most popular software's of the industry and even like in Jamie's case where we might be getting data from multiple sources we usually can come up with a good strategy to do that.

Anyway that is going to conclude today's webcast I want to thank first of all the panel for spending their time to help prospects have a better understanding of what the experience would be like and so thank you guys Caleb, Kent and Jamie very much and thank you all for everyone who attended today's webcast I hope that it was a good investment of your time and you have a better understanding of the tremendous impact that this technology can have on your business. We heard some really good things today not just modernization and digitalization and getting rid of paperwork and improving communication but increasing throughput and just a whole host of other things including making it so that we can ship 100% accurate so thank you guys so much, you can check us out at RSA Solutions for the next educational webcast thank you take care and good bye.