Production Coach

Production Coach

With complete real-time visibility of all elements of your production line, Production Coach software gives you all the data needed to take action, manage your team and make the right decisions at the right time.

Production Coach is modular in nature meaning that you can do as little or as much as you want with it. Successful deployment in your factory can be accomplished in days, not weeks or months.

Let us show you how Production Coach can make your factory more efficient.

Learn more about Production Coach, hover over the plus “+” signs to see how Production Coach gives you complete real-time visibly of stations in your production line.

Production Coach utilizes a centralized SQL database connecting both office and factory to real-time data. Web applications such as Jobsite Tracking and Timekeeping are synchronized with the Local Area Network environment.

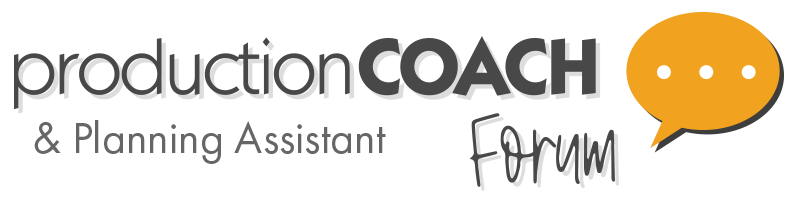

Production Coach Connects With

One of Production Coach greatest attributes is the ability to harness data, import from industry software solutions including woodCAD|CAM, Cabinet Vision, Microvellum, Cut Rite, Excel and more. Once imported Production Coach knows the products in the work order, all the parts, hardware etc.

Production Coach – Proven Results

Our clients observed and confirmed numerous gains and improvements as early as the week following Production Coach implementation.

Significant improvements in Assembly Time resulting in a measurable and considerable daily production increase.

Reduction by more than 80% of time spent searching for components and gather materials through the factory floor.

Complete visibility and control on damaged parts identification and important optimization of time to put parts back in production.

Considerable decrease of missing items in delivery, optimization of truck loading and noticeable decrease of Service Calls.

Production Coach Features

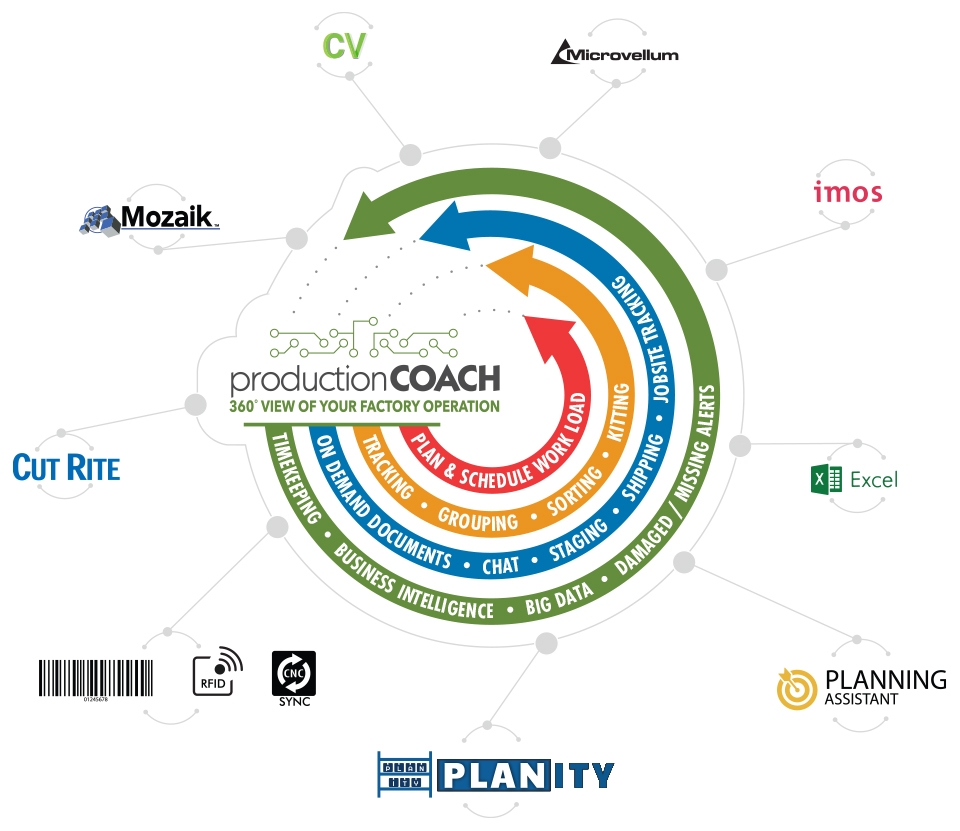

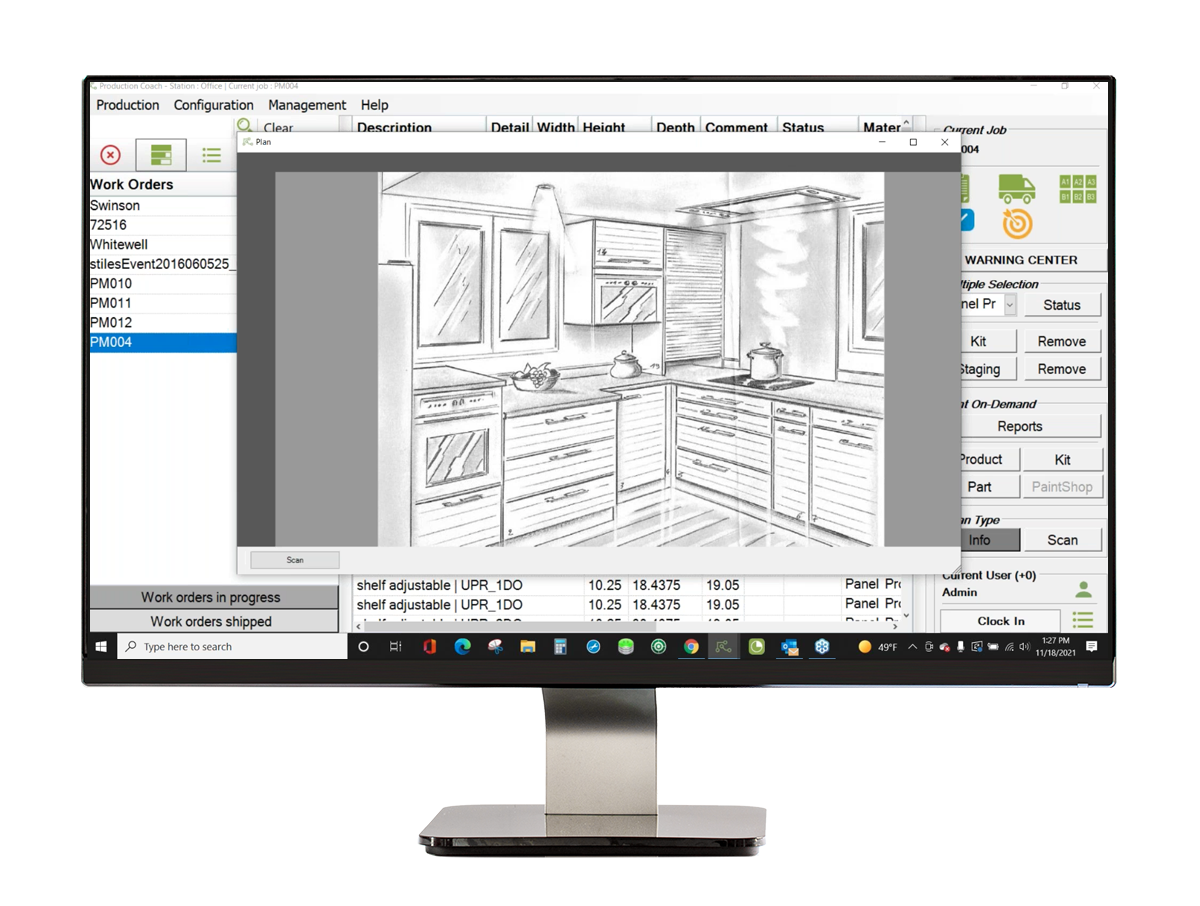

Interface

Production Coach Interface is clean and simple, basic setup includes Workorders on the left, Assemblies top middle and loose items from the assembly.

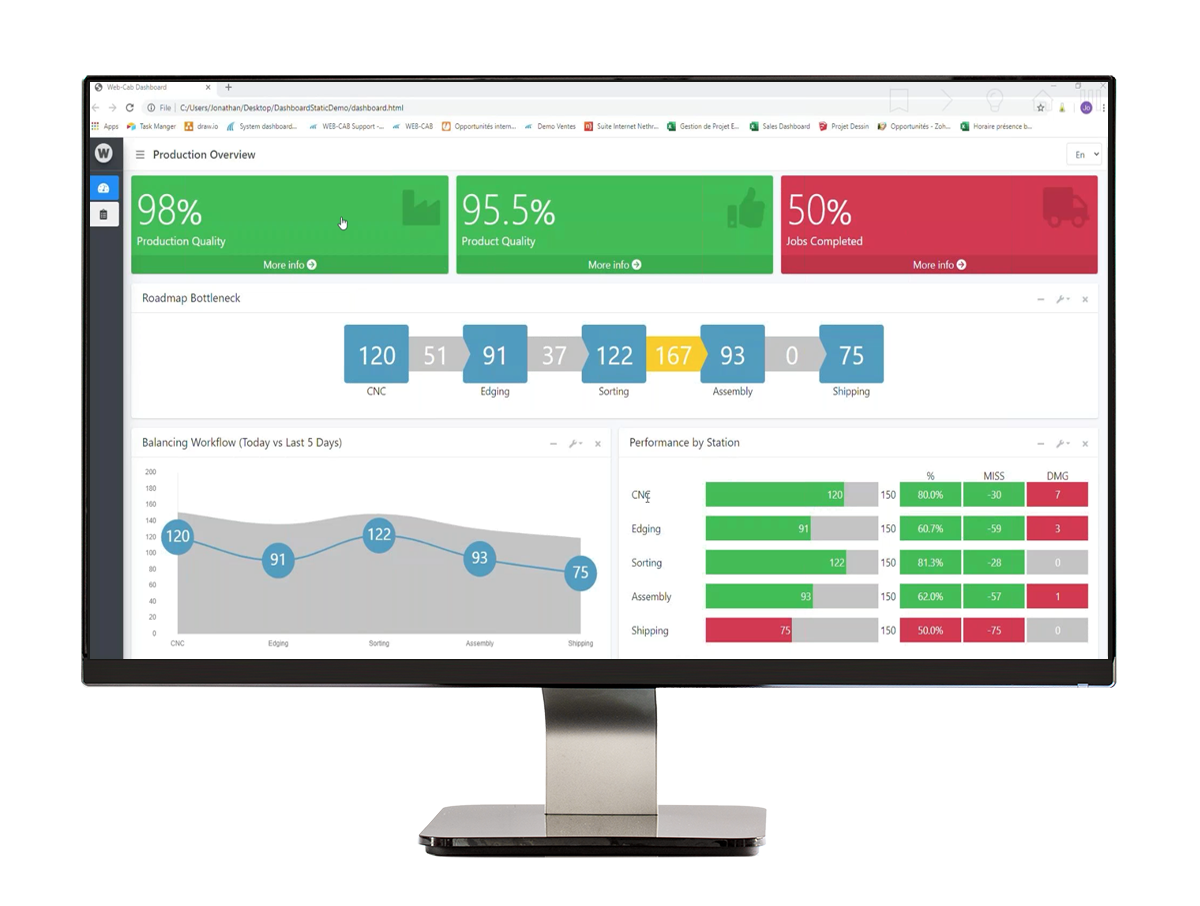

Business Intelligence Dashboard

Global vision of your production. Real-time view of important KPI such as balanced flow, bottlenecks, etc, along with BIG DATA analysis of manufacturing history.

- Make better business decisions

- Get an accurate picture of your time

- Optimize your processes

- Save time and money

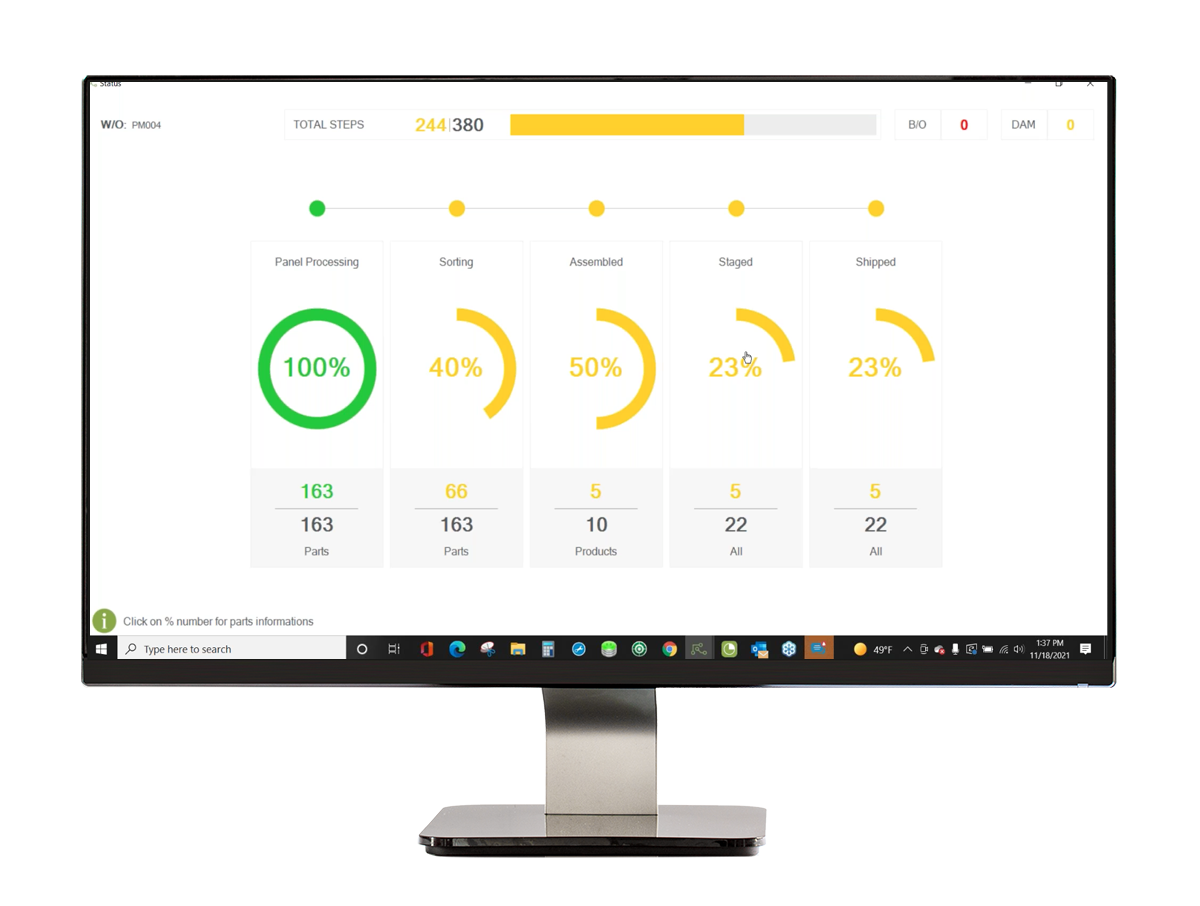

Work Order Status

See the real-time progress of work orders as they move through the factory and jobsite. See status of orders or view by work center.

- Complete status of projects

- Detailed status per station

- Visual of alerts per project

- Visual of production

On Demand Documentation

At any station throughout can have access to any documents needed for production, project rendering, elevation drawings etc.

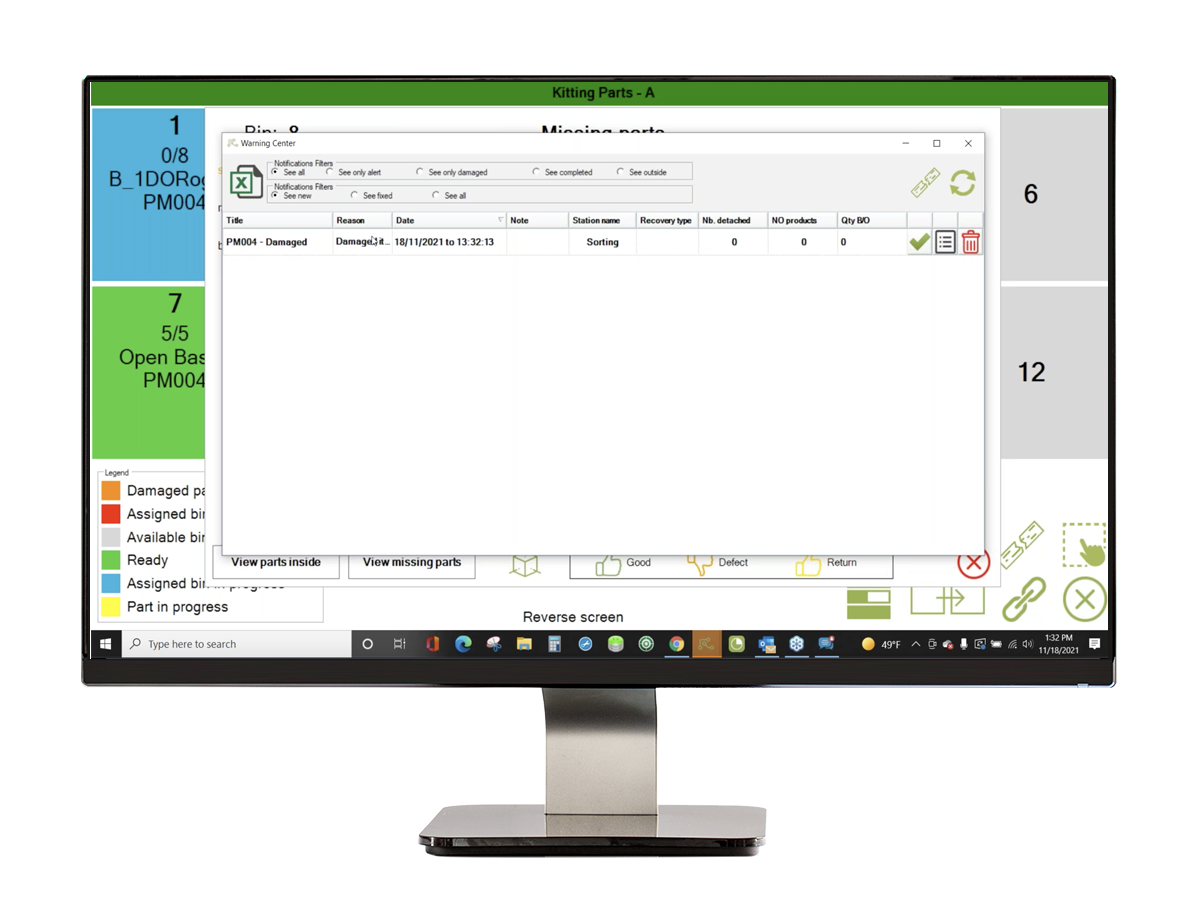

Damaged Part

Reports and alerts of missing or damaged parts are created and distributed automatically.

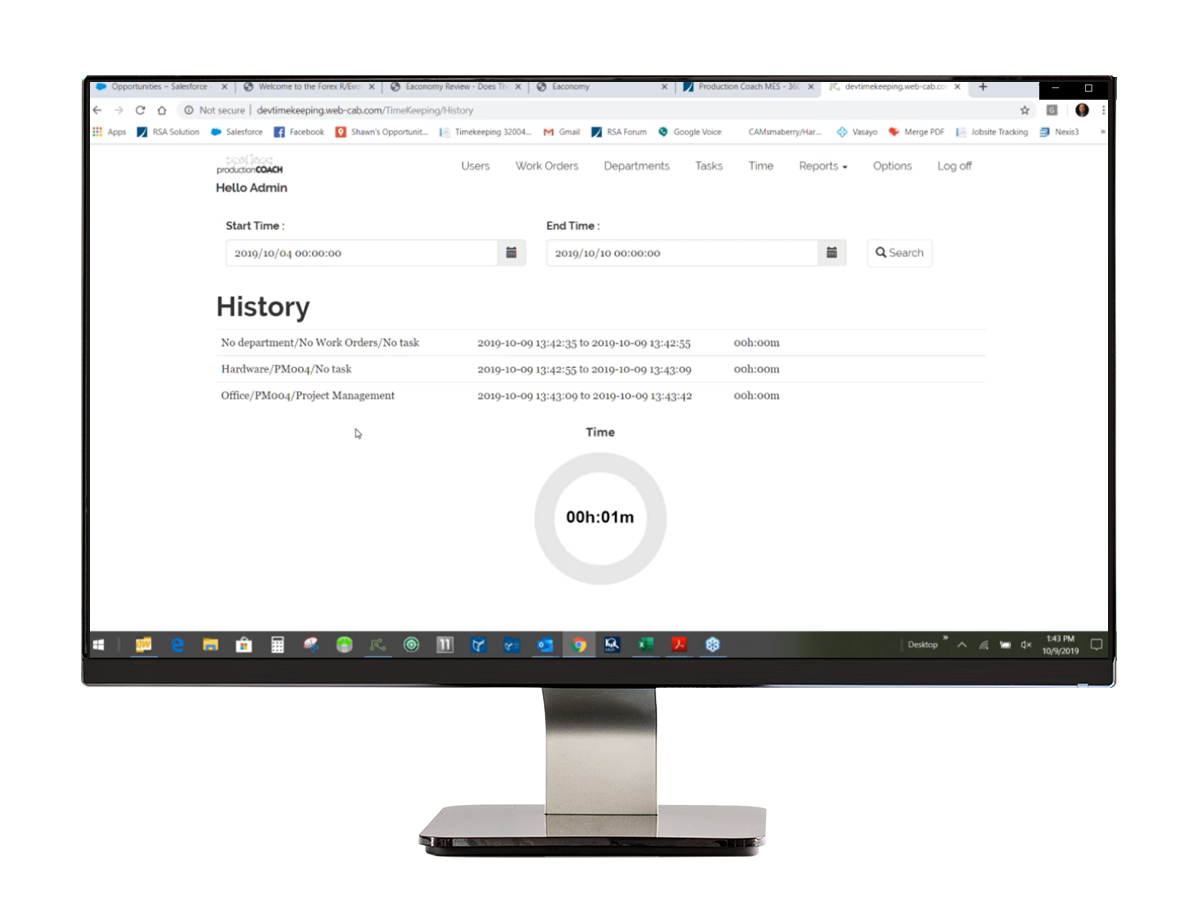

Time Keeping

Web based time keeping for payroll and work order costing.

Smart Labels

Grouping by edge material or part type for next operation, automatically updated parts status, and create damaged part alerts all from a single interface. Generate on-demand labels, control and pace off-loading and label orientation.

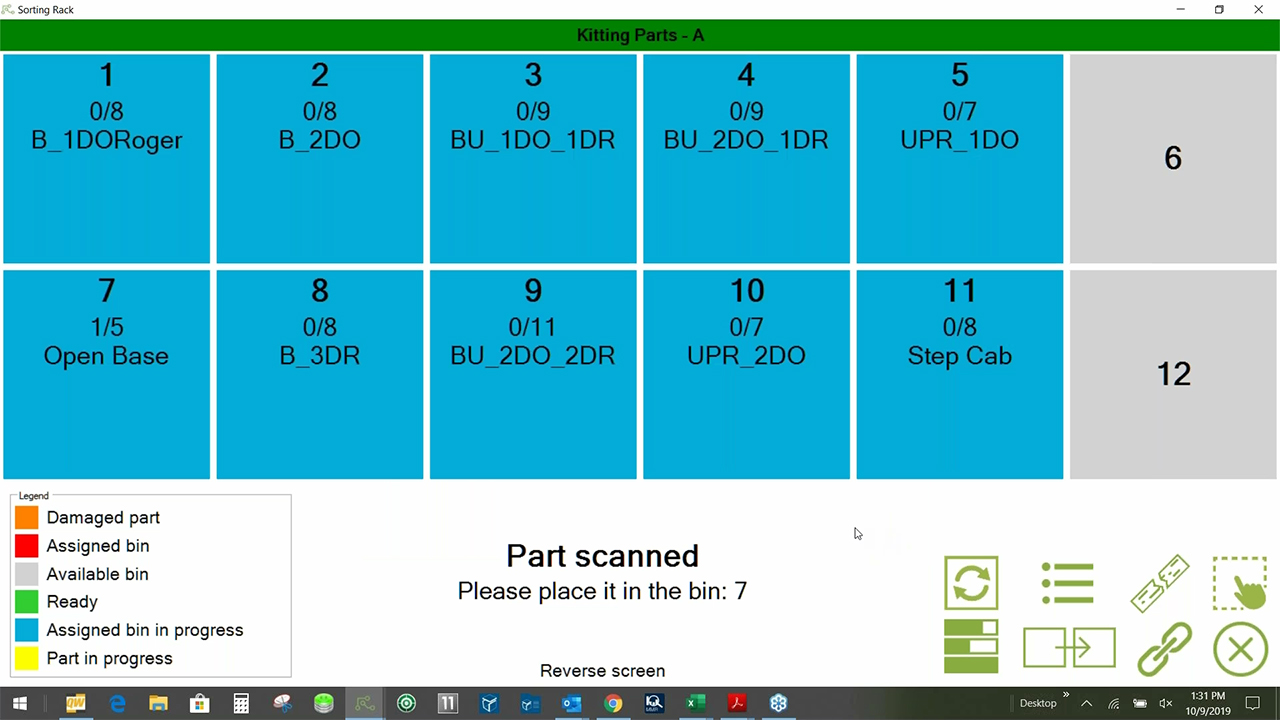

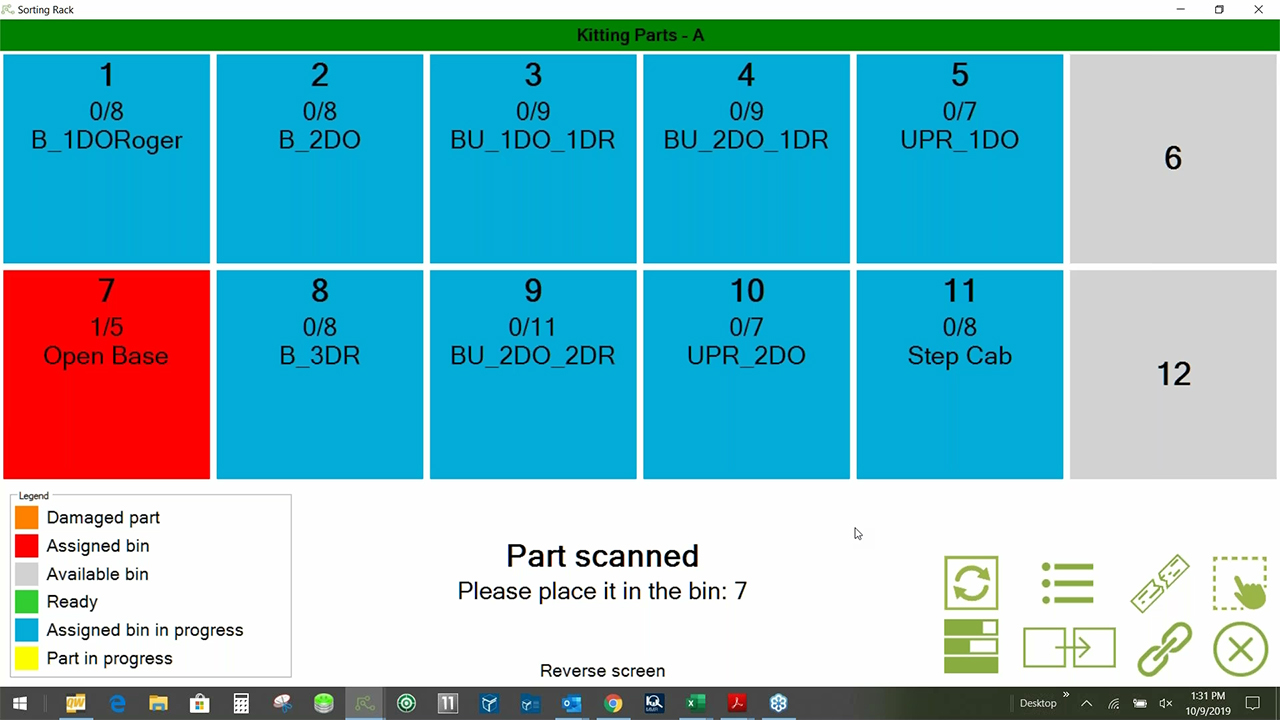

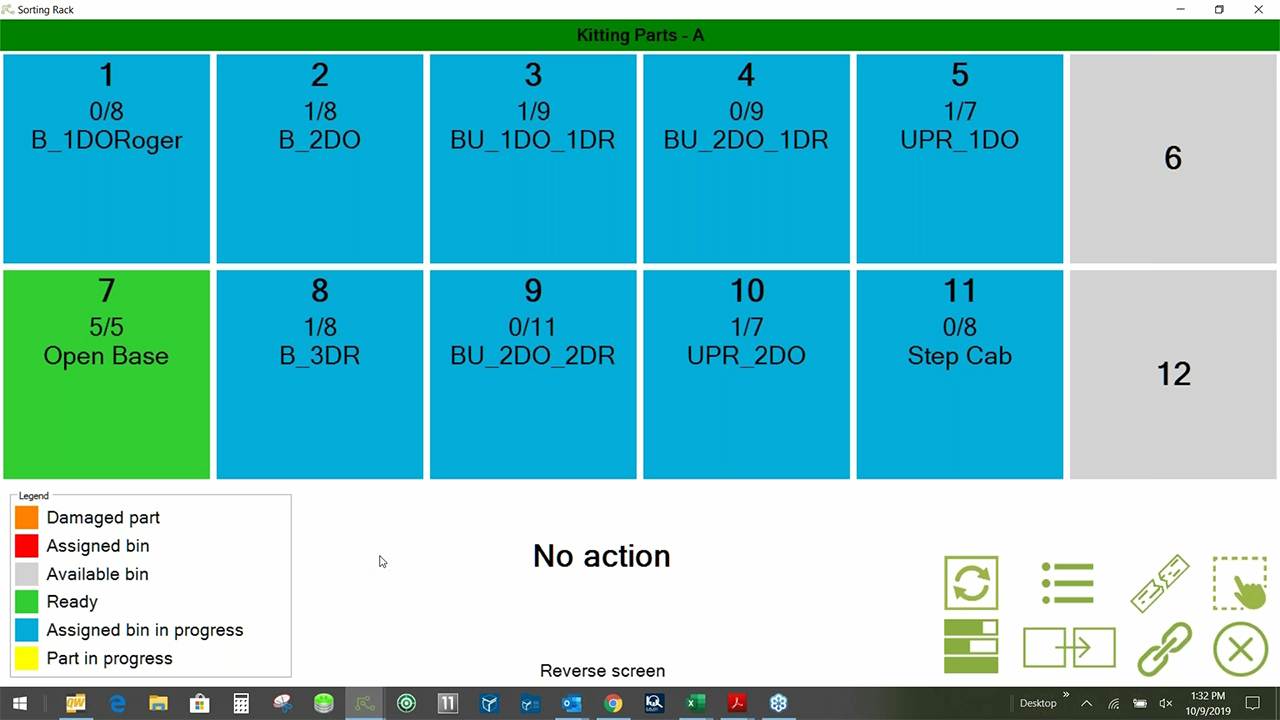

Sorting

A single barcode scan organizes parts by assembly and provides feedback for missing items. Assembly is notified of products ready to assemble. Sorting can be synchronized with other sorting stations: cabinet parts, doors/drawer fronts, drawer boxes, base assemblies, etc.

- Eliminates the need to search for parts

- Clear visual of alerts and progress

- Simplifies subsequent operations

- Better management of space and resources

Compatible With

- Mobile Cart

- Wait until all parts of a project are sorted into 1, 2 or 3 mobile carts before being sent to assembly

- Square Footage Required

- Fixed Rack

- Put in/Pull Out

- Continuous Mounting

- Takes up less space.

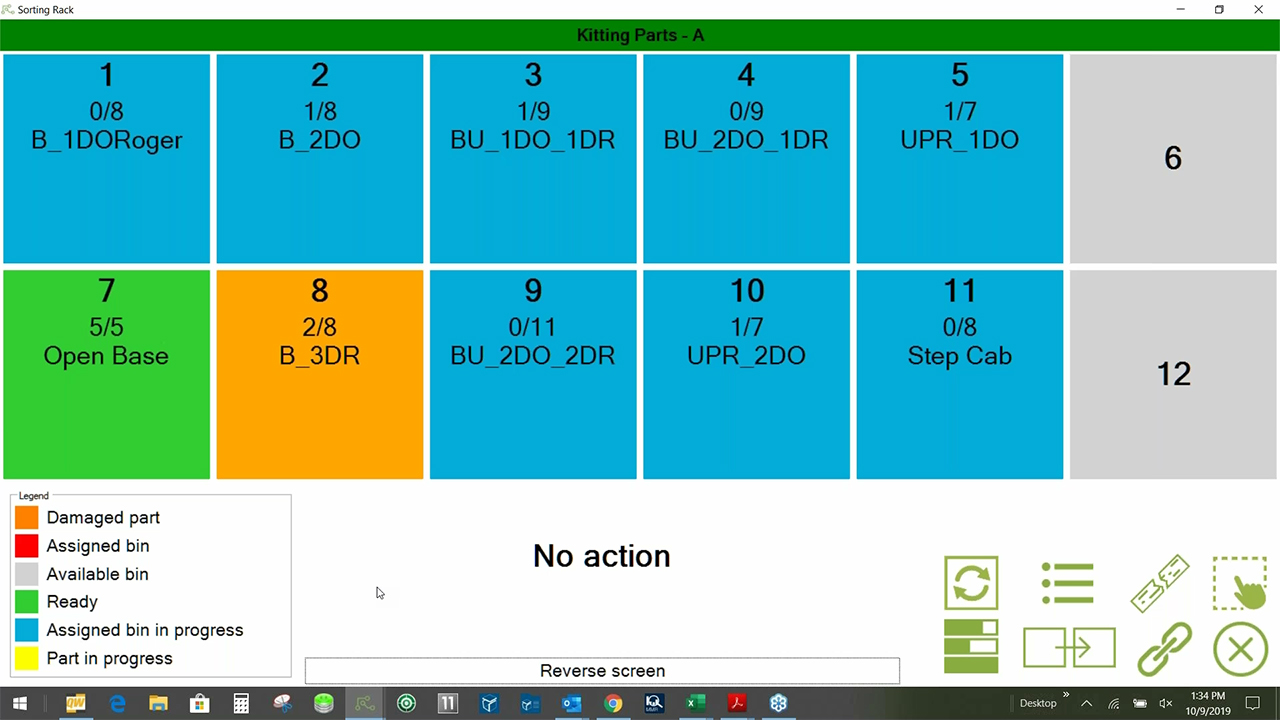

All Blue

~ Ready To Sort

Red ~ Part Assigned Location/Bin

Green ~ Project Sorted Ready For Assembly

Orange

~ Damaged Part Alert

Production Coach Before

Production Coach After

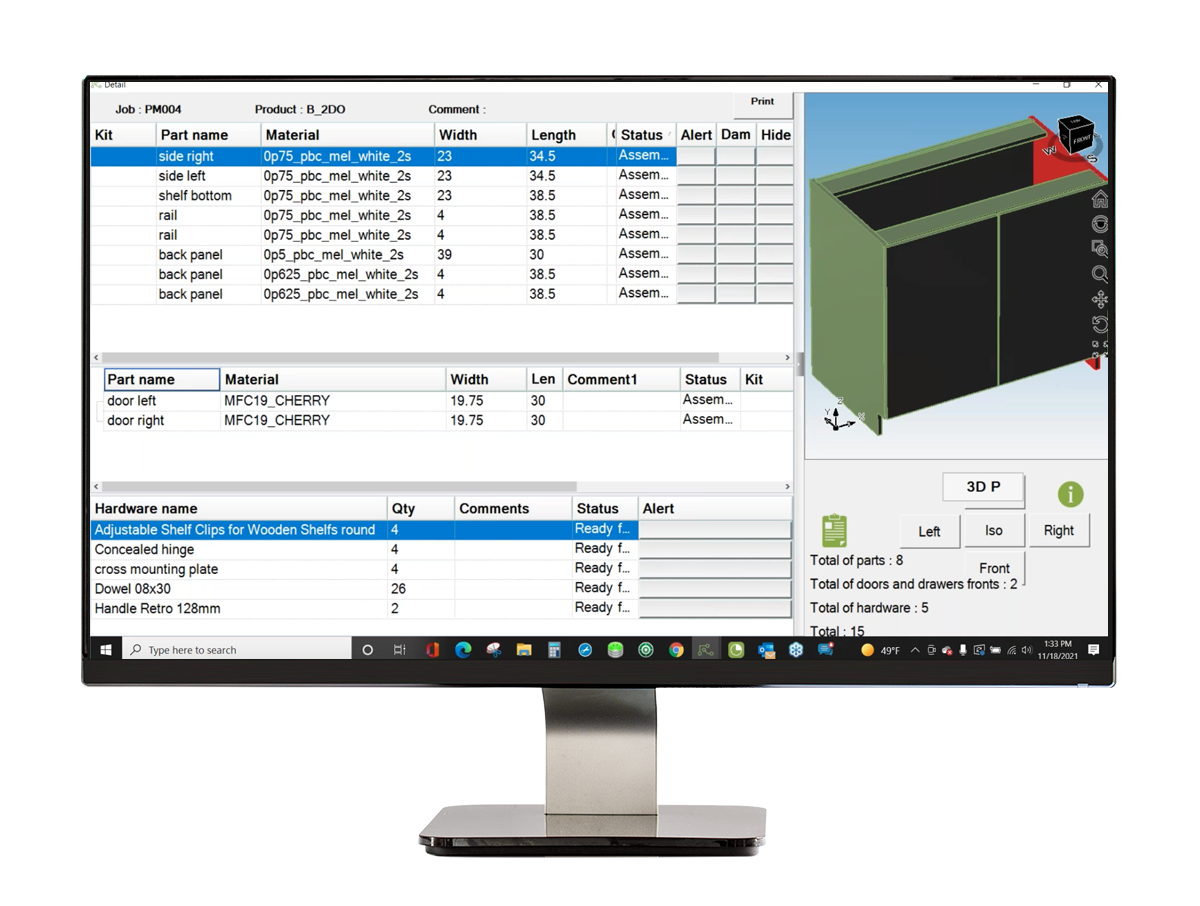

Assembly

Scan any part of the completed bin to start the assembly. See part details and part position with the assembly.Reduce the need for wasteful conversations between engineering and factory floor staff.

- Easily locate all components

- Centralization of documentation

- Prioritization and precise definition of tasks and steps

- Reduces assembly time by 50%

- Precise definition of tasks and steps

- Standardization of quality

- Quickly train new employees

- Increases employee performance

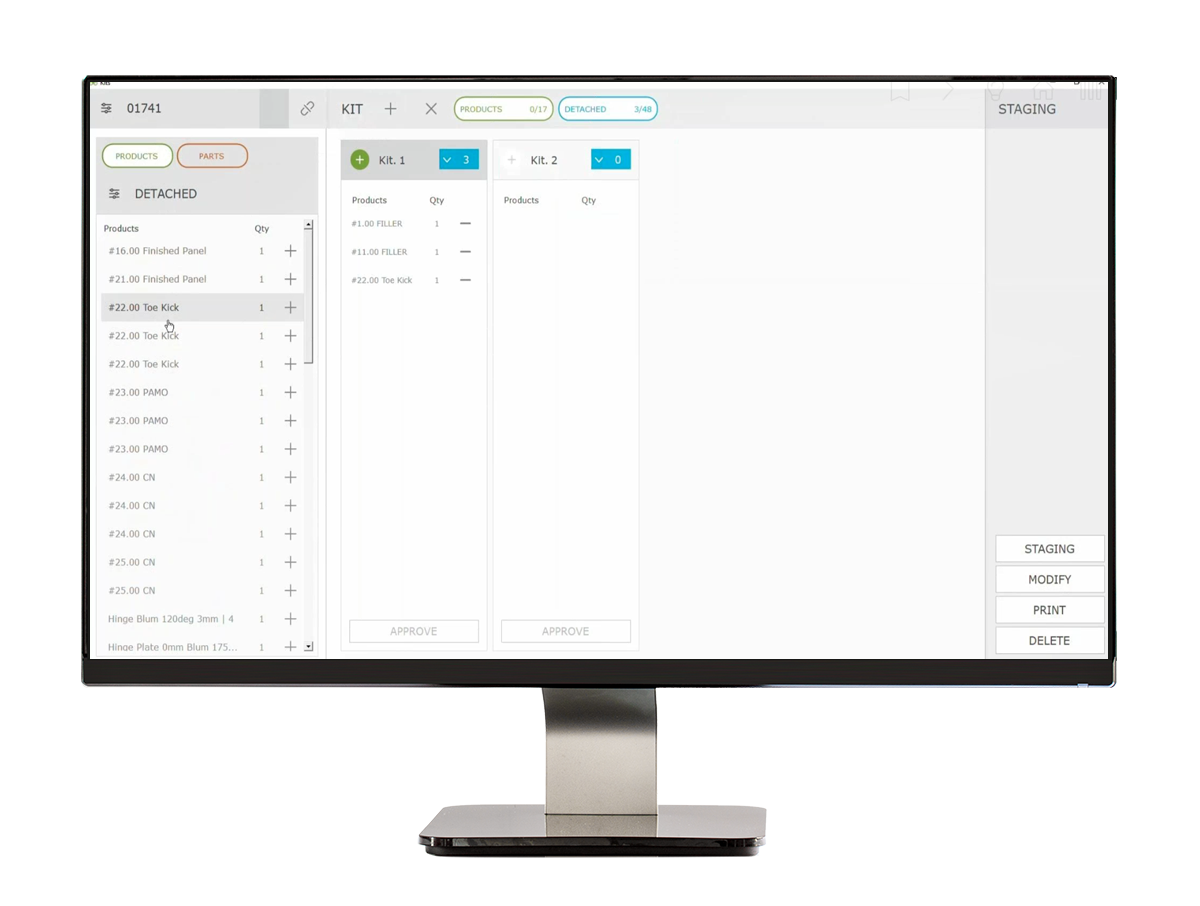

Kitting

Create kits with unique barcode of pallets, parts, mouldings, hardware, etc. that need to be included in the shipping ticket.

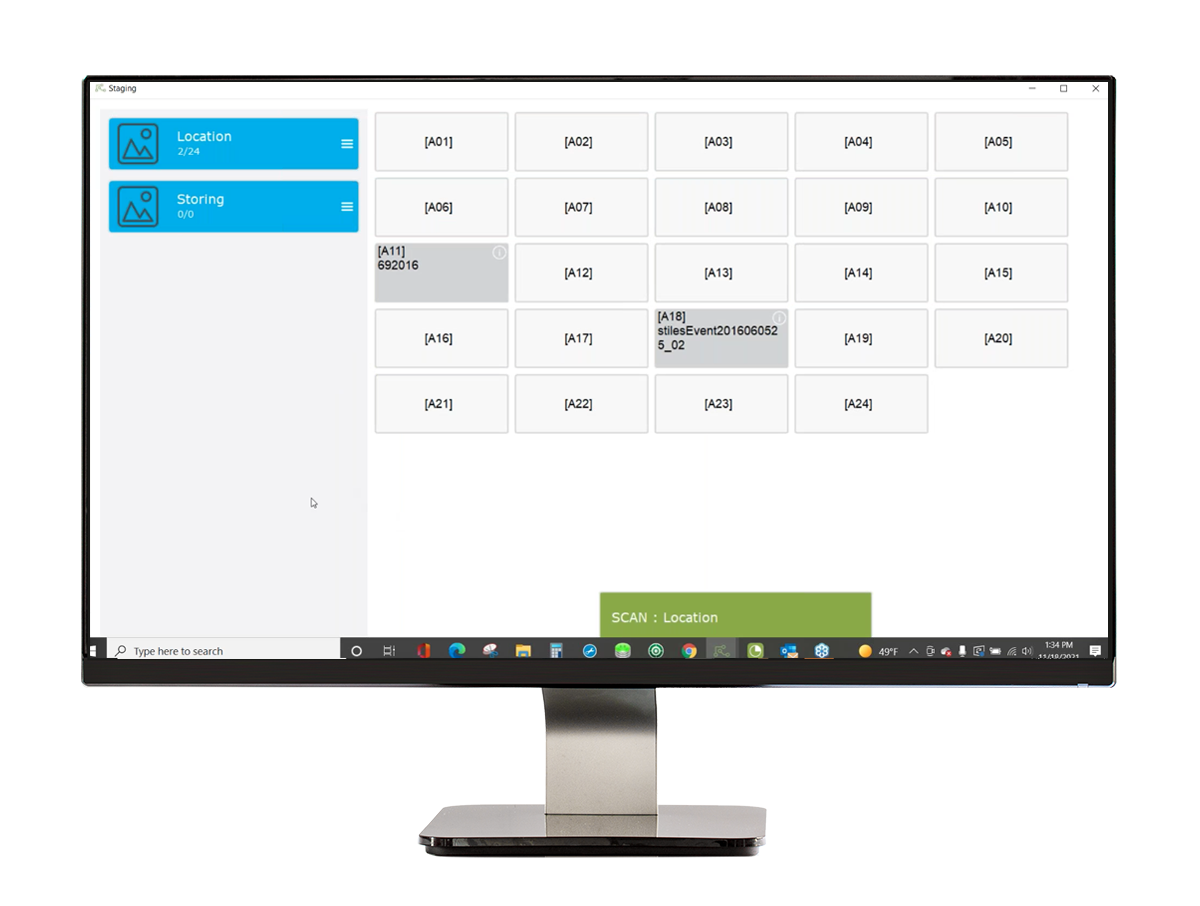

Staging

Stage products, pallets, and kits into a designated location prior to shipment.

- Optimization of space

- Organization of shipping chain

- Eliminates the time allocated to research

- Prevents component breakage and rework

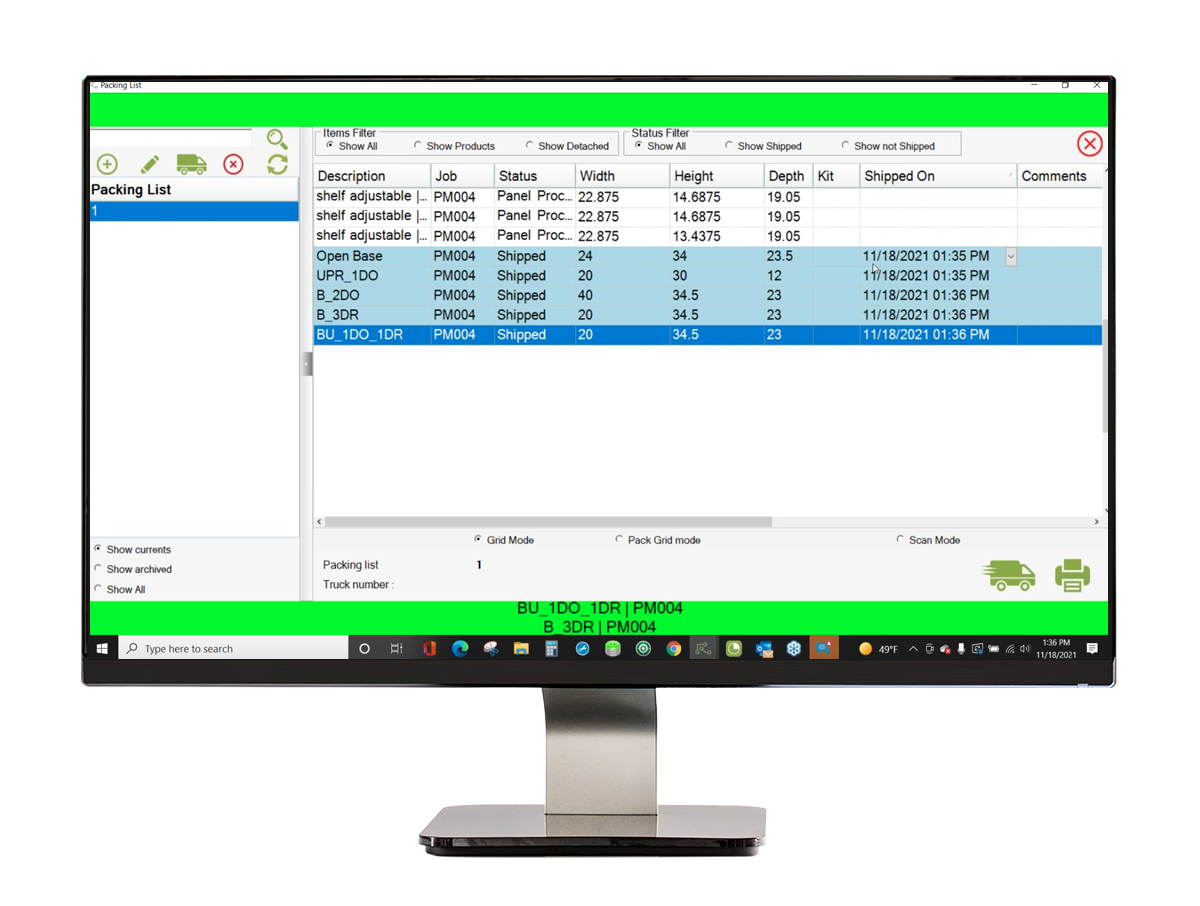

Shipping

Ensure 100% accurate shipments, 100% of the time.

Generate instant and electronic verification of everything scanned onto the truck.

Cost Of Errors:

- When placing an order = $1

- When processing an order = $10

- During transformation = $100

- At the client = $500 to $1,000

- Eliminates incomplete shipments

- Real-time load validation

- Remote access to documents

- Management of damaged parts

Jobsite Tracking

Web application for scanning products and kits off the truck at delivery and/or at installation. Data is synchronized with Local Area Network environment.

Production Coach Customers

Former President of AWI Discusses Production Coach Integration

Read more about Greg’s move to Production Coach and how it has streamlined his workflow.

Ridge Crest Custom Cabinetry – Pacific Crest Building Supply

“One of our most important goals with Production Coach was to eliminate the waste of paperwork on our production floor…”